HEEDS has it already

But now, since version 2021.1, Simcenter STAR-CCM+ lets you create Surrogate Models (Meta-Models or simply Response Surfaces) directly in Design Manager as well. This is great news and Simcenter STAR-CCM+ provides today multiple relevant benefits:

- complex flow simulations which may take hours or days to be evaluated, can be replaced by a simple model that is being computed within just seconds

- You are able to assess local parameters’ sensitivity using distributions and thereby increase robustness and ensure confidence in results

- Increase the accuracy of the 3D components in your system simulation

Surrogate Models

Let´s take a closer look on the new Design Manager´s Surrogate Models. “A surrogate is a predictive function that returns an estimated response value for a given set of numerical input parameters”. This means with a given set of training data we can predict a response of our simulation for an unknown set of input parameters. One of the most common surrogate methods is the Kriging Method which is also the default option (out of 3 option) in the Design Manager. The figure above shows an example of the Kriging Method. Here we have two input parameters, x1 and x2. The red cubes represent results from design runs and the surface represents the calculated surrogate model for this response, fitted through the training data.

How to set up a Reliability Study with Star CCM+

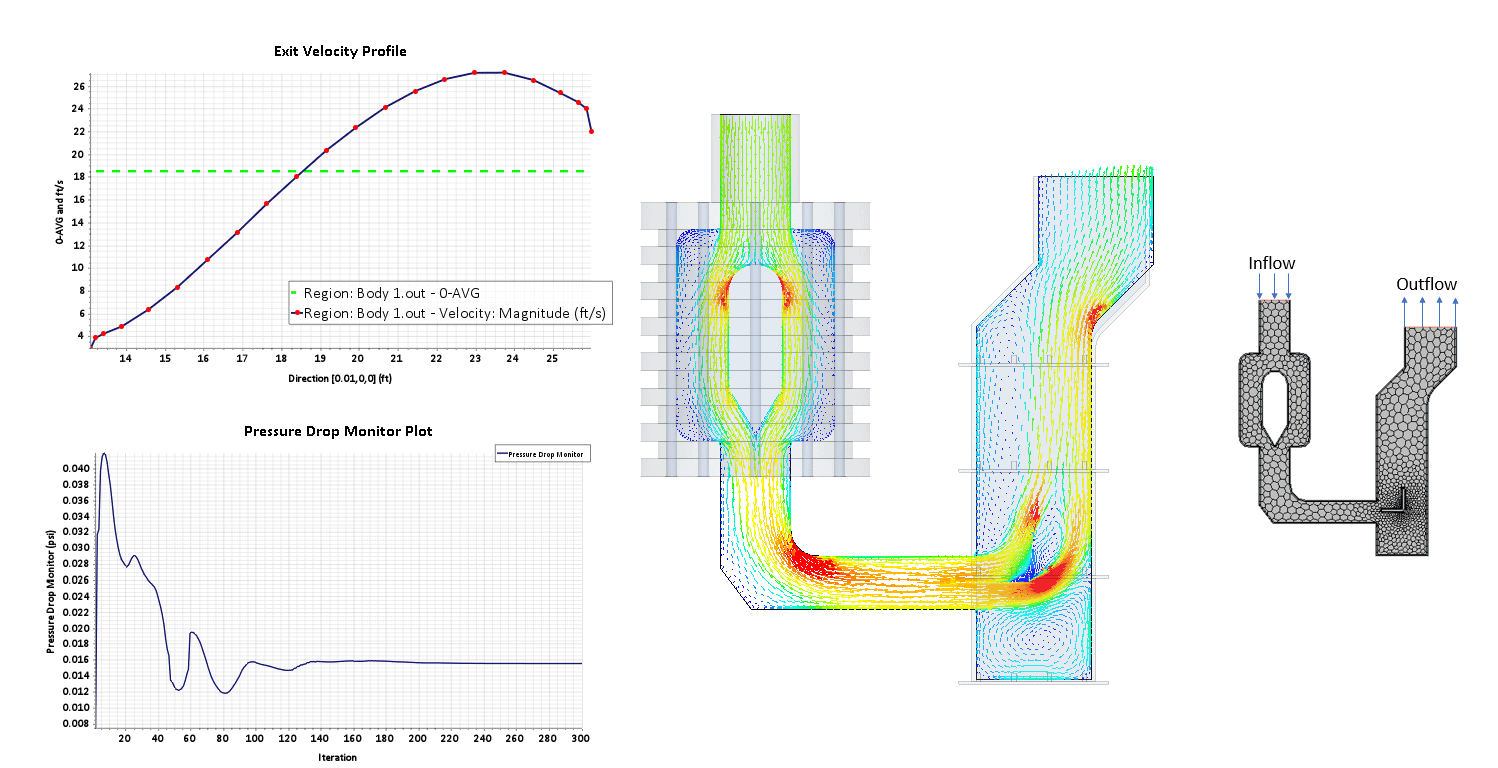

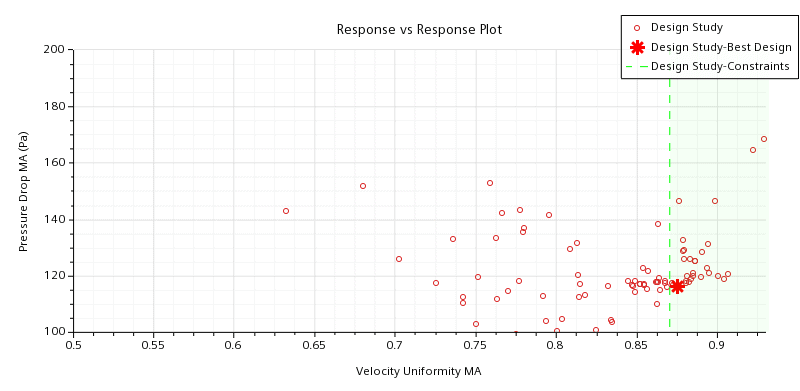

If we were interested in a Robustness and Reliability study the Surrogate Models come in quite handy. For exemplification we look at a study of the flow in an exhaust pipe. In the first step an optimization of pressure drop vs. outlet velocity uniformity revealed a Best design close to the minimum constraint of velocity uniformity. To asses if this design can be the best from production perspective we now can perform a reliability study based on a response surface.

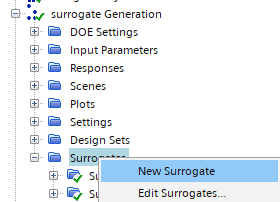

To get started we first need to create a set of training data form a Design of Experiment DOE. The DOE is restricted closely around the best design found and sample are created using Latin Hypercube method. The surrogates are added to the design study by adding them to the new “Surrogates” node:

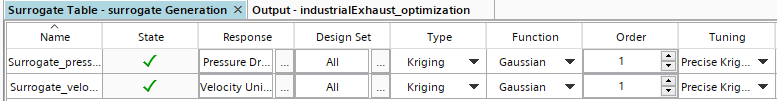

Here we set our two objectives and finetune the calculation of the interpolation method in the Surrogate Table. Once the training data are computed and the surrogate model is automatically built, we can assess its accuracy using Cross V and PRESS residuals. The Cross V residual and PRESS residual values are estimates of the error that you can expect in predicted values. These residuals are in the same units as the responses and their lower values indicate good accuracy. The residual estimate is based on the validation scheme that sets aside a group of variants from the training set to validate the performance of the surrogate method. Due to the randomness of the grouping process of the cross validation scheme, you are advised to perform cross validation multiple times. Each cross validation yields different results.

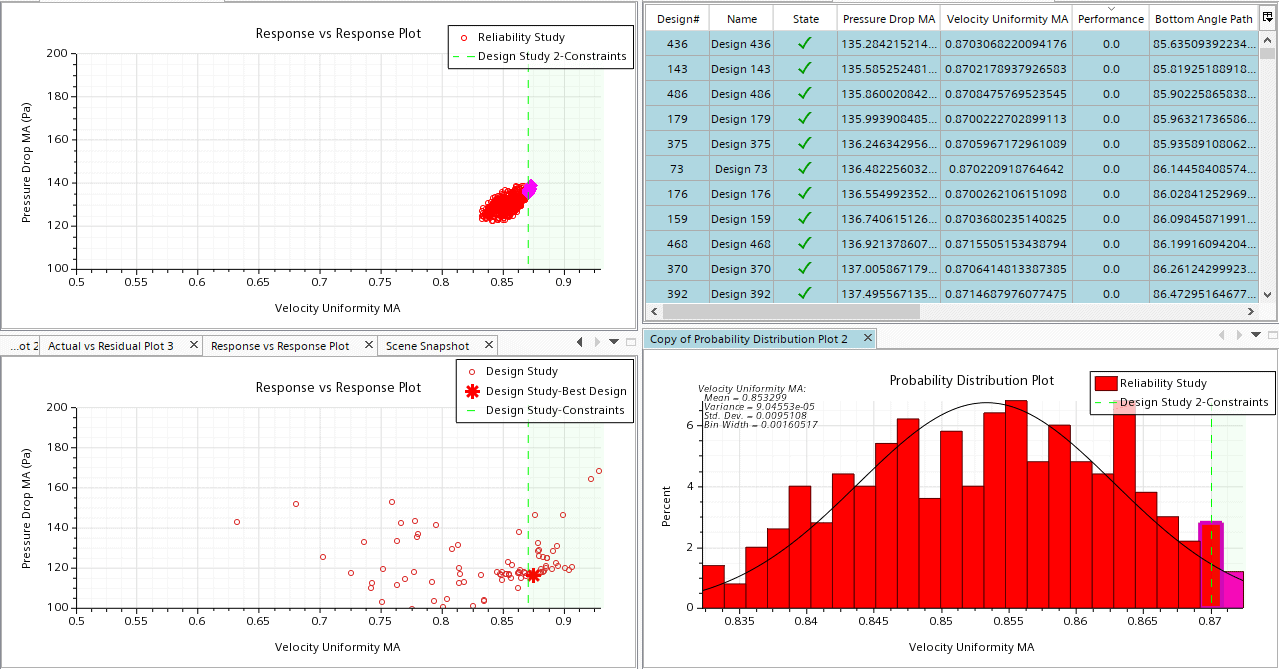

Now that we have created and validated two surrogate models for two responses we can set the model in action in a 3rd study in our Design Manager project, the Reliability study. For the input we can select distribution function to specifies the type of probability distribution to use. The probability distribution is centered around the Baseline Value which corresponds to our Best Design and describes the likelihood that an input parameter will take a particular value. For the industrial exhaust manifold, we specify a relative triangular variation of ±3.5 %.

Generally, for a reliability study to be accurate, the study must consider a high number (hundreds to thousands) of permutations around the Best Design. But this in no problem for the evaluation with our surrogates. Finally, we can now assess the probability of failure of the designs using the probability distribution plot.

We can see here that many designs fall below the constraint imposed, even if we provided a symmetrical distribution ±3.5% for all parameters. This means the design is not reliable with the given probability of input parameters.

How to set up an Optimization Study

You can use the new Surrogate Models as well for an Optimization Study. The setup follows essentially the same steps as above described for the Reliability Study:

- DOE for training data

- Build Surrogate Model

- Asses Surrogate Model

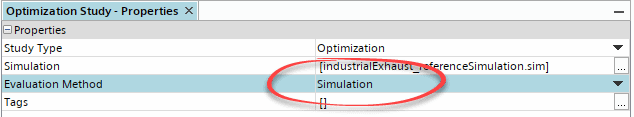

We only need the change the Study Type to Optimization with Evaluation Method “Surrogates”. It is optional, yet, recommended to start from a global optimization to limit the design space. Once the variants are evaluated by the Surrogate Model and the optimization converged, we can find the best suitable designs, change the Study Evaluation Method to Simulation and select Rerun Design. This ensures that our optimal designs are actually simulated results and simulation results are available.

I hope this has been useful for you, and as usual, do not hesitate to reach out if you have any question regarding this or anything else regarding Simcenter STAR-CCM+, Design Manager or Optimization in general. The place to reach out to is support@volupe.com.

Happy optimizing!

Read more:

How to run Design Manager Projects

Simcenter Nastran

STAR-CCM+ field function syntax, part 2

Rotating Flow Part 2