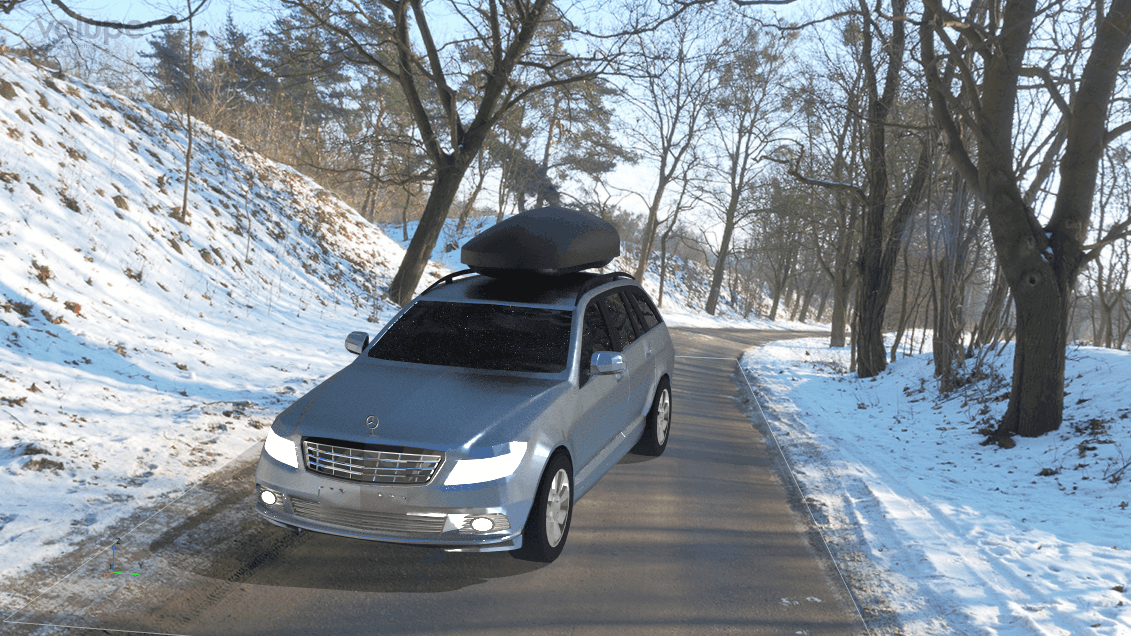

So, winter is over, and we are heading towards spring here in Sweden! Unfortunately, the presence of snow down here in Gothenburg was rare and if you still want to enjoy some ski vacation you need drive far. This year me my family and friends went on a one-week winter vacation in the north of Sweden. To be able to get all our necessary and unnecessary stuff and equipment with us we borrowed a roof box to mount it on our car.

So, winter is over, and we are heading towards spring here in Sweden! Unfortunately, the presence of snow down here in Gothenburg was rare and if you still want to enjoy some ski vacation you need drive far. This year me my family and friends went on a one-week winter vacation in the north of Sweden. To be able to get all our necessary and unnecessary stuff and equipment with us we borrowed a roof box to mount it on our car.

Driving around with roof box, I started to wonder how much such a box on top influences the resistance, driving performance and fuel consumption. And if the position in longitudinal directions, as the only adjustable parameter, affects those characteristics. Ultimately, I wondered if there is a best position to mount the box on our car and thereby a way to reduce the resistance by only moving the ski box.

Well, with help Simcenter STAR-CCM+ we are about to find out.

We have a medium sized station wagon in the family and were driving up north (not in the Alps!) on Swedish country roads for approximately 600 km. This frames the setup for a steady simulation at a constant speed of 100km/h. Let´s say our car consumes 6l/100km without the box on the roof and that the fuel consumption is proportional to the resistance of the car. Then we would consume 72l fuel on our round trip journey without the box.

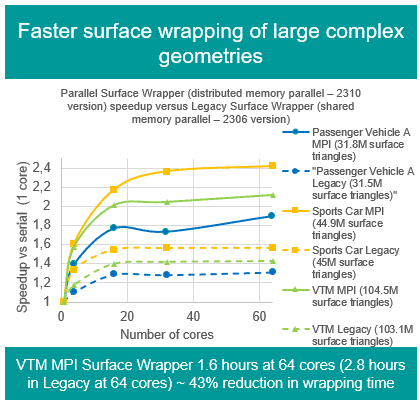

For a simulation, first thing we need is the geometry of a car that comes close to what we have. GrabCAD or 3D CAD BROWSER can be good source for CAD models. Some of the models are native CAD, some are neutral CAD, yet often are they too detailed or defective for an aerodynamic analysis of external flow. They may have overlapping faces or gaps. Luckily Simcenter STAR-CCM+ comes with the Surface Wrapper that can be used to provide a closed, manifold, non-intersecting surface as an intermediate step between CAD and mesh.

In my case of the car, Surface Wrapper helped to create a clean outer shell of the my car by

- Closing holes, gaps, and mismatches (like intersecting surfaces)

- remove internal features (like the interior)

- Simplify the surface geometry by removing unwanted detail (like wipers)

The Surface Wrapper also allows to setup refinement of geometry details. In my case like the roof rails, front grill or the rims.

I used the Surface Wrapper by Shrinking to get the external volume for the car and the ski-box separately. The reason is simple; Every time the ski-box geometry is updated by its longitudinal position, its operation pipeline goes out of date and requires an update of the Surface Wrapper. For a geometry that is refined several times, this would extend the computational time.

I used the Surface Wrapper by Shrinking to get the external volume for the car and the ski-box separately. The reason is simple; Every time the ski-box geometry is updated by its longitudinal position, its operation pipeline goes out of date and requires an update of the Surface Wrapper. For a geometry that is refined several times, this would extend the computational time.

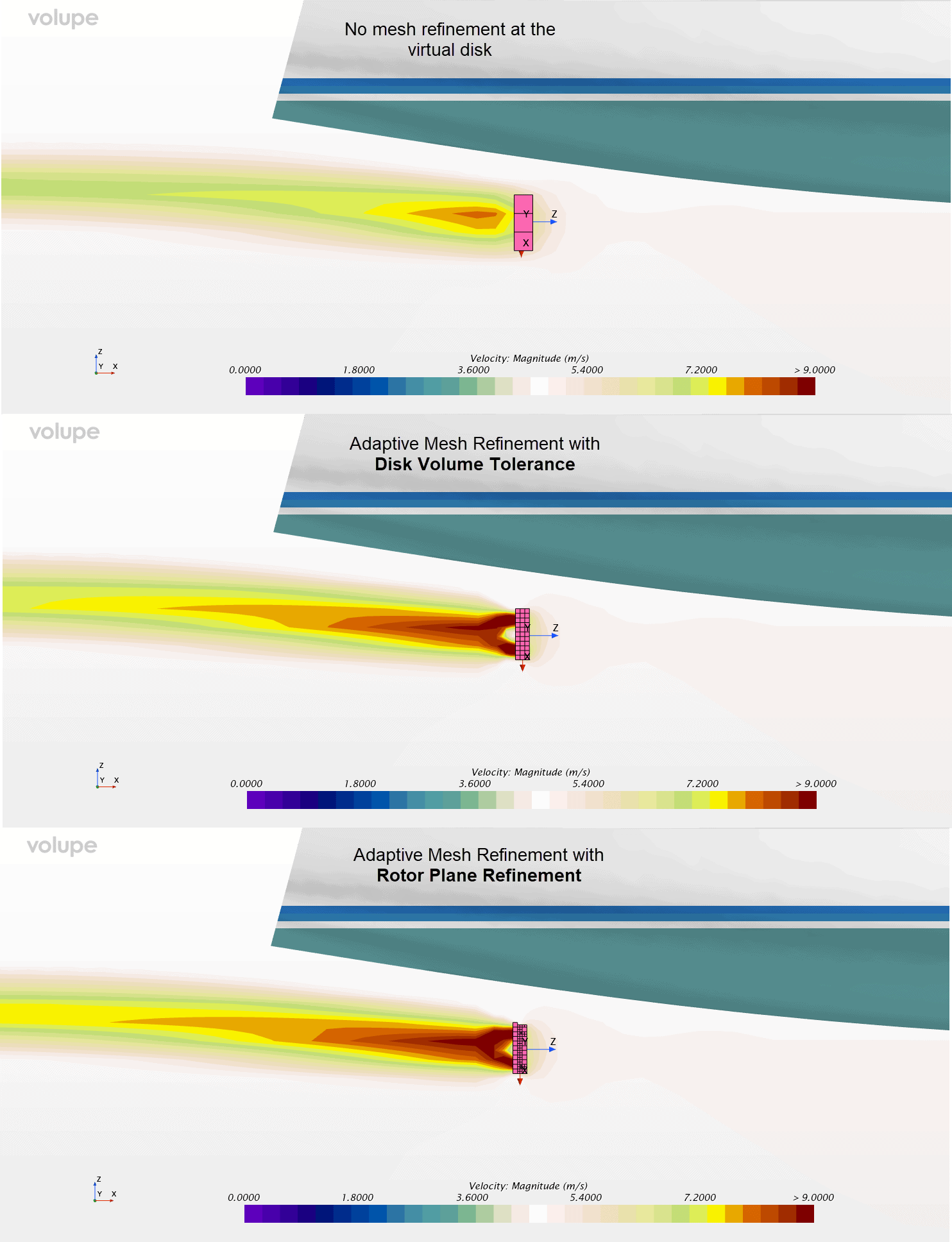

However, an update of the Automated Mesh operation is of course inevitable. The mesh is subsequently generated based on the 2 wrapped surfaces (car and ski-box), with surface refinements similar to the ones applied during Surface Wrapper operation and volumetric refinements in the cars wake.

Adding the box at a centralized position on the roof, results -as expected- in an increase of our resistance by 23% and thereby the fuel consumption jumps immediately up with 1.4 l/100. This means an additional consumption of 17 l on our journey.

Fair enough, we need to pay the price for the extra space. However, the box changes as well the balance of the vertical forces. And disturb the flow field about the car as well with separation and vortices from the downwash in the wake. Which the passengers experienced as uncomfortable wind noises.

Time for a design study!

With the setup of a parameter controlling the position of the ski-box in a geometry Transform operation, we are able to fully automate the analysis of additional locations of the box with the help of Design Manager. To start with I wanted to know whether the position in longitudinal direction correlates with the resistance. I considered therefore only the outermost positions possible by moving the box 25 cm forward and backward respectively.

So, Design Manger is taking over with a manual Design Study. No extra licenses are required! In the end I found the following relation: Increasing the distance of the longitudinal box position from the front, yield less added resistance. The relation is almost linear in such a way that an optimization is like to end up with the most rear location as well.

If we split the drag instead into drag from the box (relative to the cars drag without box) and additional drag on of the car due to the presents of the box, then we can see that the box has the same drag at the middle and rear position and that added drag difference results only from interaction between car and box.

In terms of added fuel consumption, we could have saved about 2 liters of fuel on our entire journey by moving the ski-box to rear position. Frankly, this doesn´t sound like very much, particularly with the assumptions I made at the beginning, but this shows that there is an impact and a trend on how the position affects the resistance, a parameter easy to adjust. And even small savings can contribute if we combine them. Some say that mounting the ski-box in reverse direction saves most but for the next coming winter season, when it´s time to put the ski-box on the car, I will definitely reconsider where I put it in longitudinal direction.