Simcenter STAR-CCM+ comes with the design space exploration tool Design Manager; the fast track to innovation. Design Manager offers several types of design study by which you can explore the design space of your product and find solutions you might not have considered otherwise. In Simcenter STAR-CCM+ 2206 a new study type (Smart Sweep) was introduced to accelerate usage of design sweeps. Learn in this week´s blog post more about Smart Sweeps, their advantages and how set them up in Design manager for two design variable flow problem.

About Smart Sweep

Design studies in Simcenter STAR-CCM+ are divided into two categories: performance assessment and optimization. But before running those you can run a CAD robustness study as well to check the geometric validity of designs in your design space. Best of all, a specific license is only required for the optimization studies. This means that you can come far in your design exploration with the standard STAR-CCM+ license.

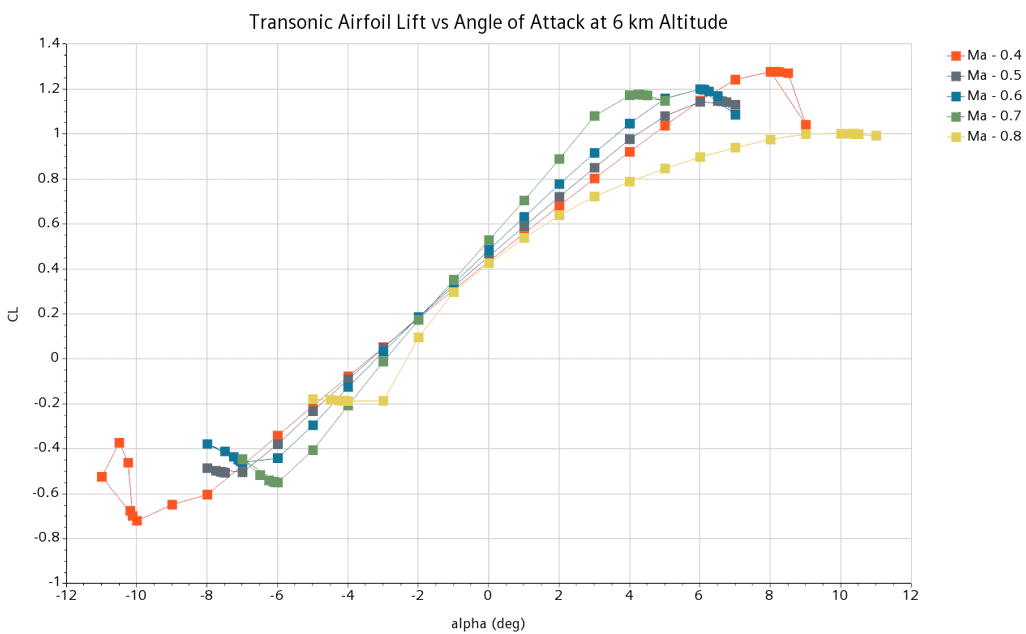

The all-new Smart Sweep feature belongs to the performance assessment category and allows you to automate design sweeps faster. Applications that need to capture a range of values within several operation points such as performance maps for rotating machines, propeller curves or airfoil stall angle are studies that benefit clearly from Smart Sweep.

Stopping criteria based on response values can be used to avoid infeasible cases. Previous design results can be used for initialization of subsequent sweep points in the study – increasing convergence robustness and reducing simulation time.

However, Smart Sweep can be used to identify the design of interest in any kind of application with more than one parameter by stepping through the values sequentially. In the following section we apply a Smart Sweep on a simple pipe flow example with mixing chamber. To the main flow we add a secondary and tertiary flow with different temperatures. Eventually, we are interested in the temperature uniformity at the outlet as a function of the secondary and tertiary mass flows.

How to set up a Smart Sweep

In a Smart Sweep, you specify input parameters, responses, plots and scenes as in conventional sweep studies. However, in the Design Table you add one row per sweep (kept constant during stepping). Here we decide to test three different conditions for the mass flow on tertiary inlet pipe (0.05, 0.1 and 0.15 kg/s) and step through a number of inflow conditions at the secondary pipe.

There can be only one stepping parameter, which is selected from the input parameters of the Smart Sweep study (MassflowSecondary and MassflowTertiary pipe). Choose the stepping parameter from the Stepping Parameter child node and specify the step size.

The number of design runs and their distribution within a sweep is controlled though the sweep Stepping Parameter, Bisect Criteria, and Stopping Criteria.

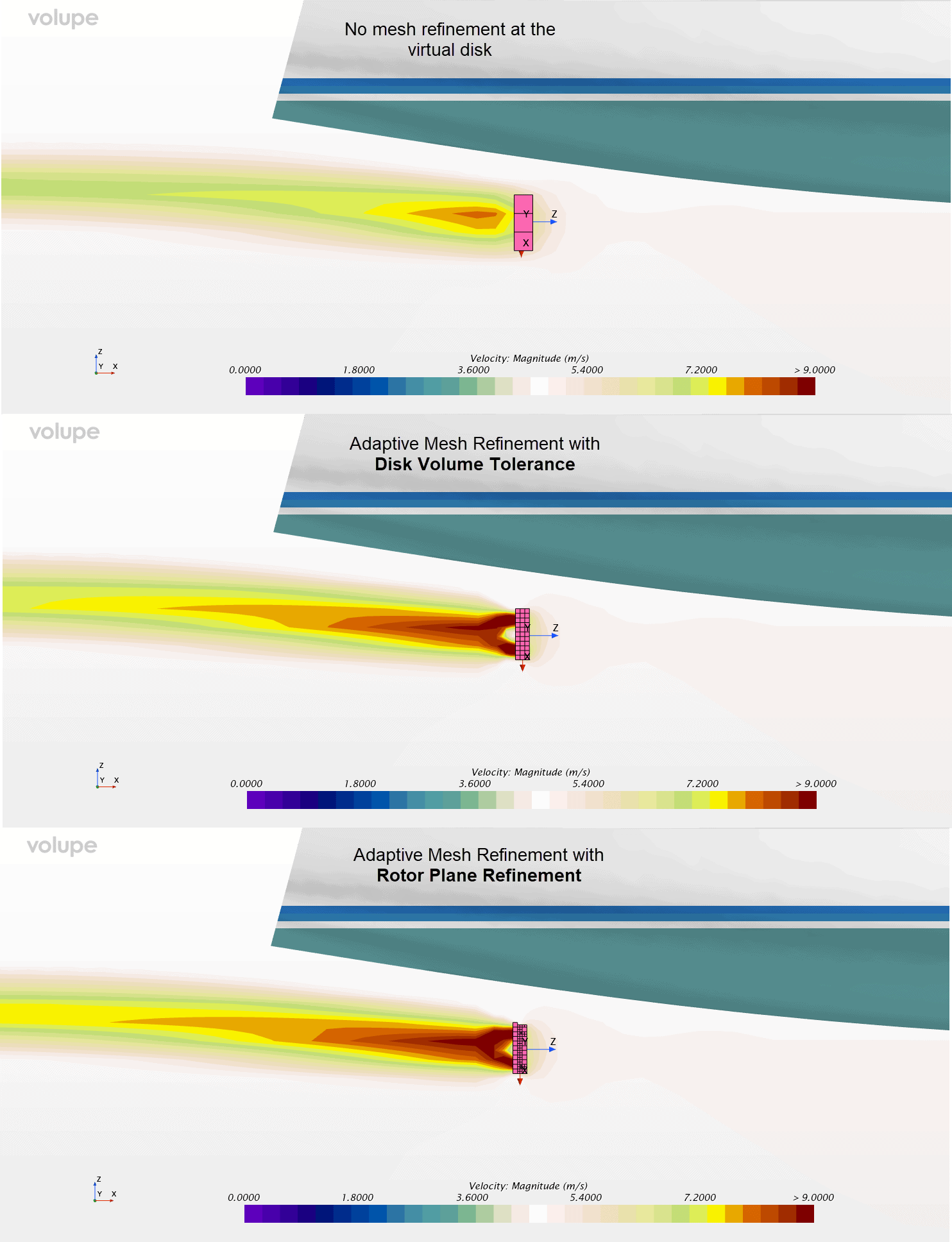

Bisect criteria are based on the design responses and control the size of sweep stepping. When met, the step size within a sweep series is halved continuously for each further design run until the stopping criteria of this sweep are fulfilled. An absolute Minimum or Maximum value of the response can be specified from which the bisect begins once the response reached that value. However, in our case we don´t know the maximum temperature uniformity that can be reach beforehand. It is therefore more helpful to use the Percentage Change criteria type.

The Percentage Change value given with respect to the minimum value or maximum value from all previous designs. Means the criteria is redefined as soon as we find a new minimum or maximum respectively. We can define a positive percentage change which is met when the percentage increase from the previous minimum design value exceeds this value. For a negative percentage change, the criterion returns true when the percentage drop (from the previous maximum design value) exceeds this value. The figure below exemplifies negative percentage change of -0.001%. Once the Bisect Criteria is met, we can see that the Designs moving towards the obtained maximum with continuously bisected step size. Until the one stopping criteria is met; here the maximum number of bisects.

The Stopping Criteria determine when to stop the study. Useful criteria are for instance a maximum limit on the stepping parameter. In our case 2 kg/s mass flow rate at secondary inlet. But also, the response criteria off a maximum temperature uniformity of 1.0 or stopping after consecutive error designs are reasonable to avoid unnecessary evaluations.

Speaking of unnecessary evaluations, it is now finally possible to reuse some previous results for further design runs! Select the Smart Sweep Settings and enable the reuse properties:

Reuse designs within search

When activated, the current design reuses the converged solution from the previous successful design run of this sweep series to achieve a better converged solution.

Reuse designs across search

When activated, the first design of the current sweep series reuses the first design solution from the previous sweep. In the case of an unsuccessful first design, Design Manager searches further for the next successful first design in downstream sweeps.

Comparison to Sweep

The over all result of the comparison study is essentially the same. Without the use of the Bisect Criteria, we get 120 designs in both studies, subsequently stepping through the design space. However, one of the advantages with the Smart Sweep is the automation. We automatically get the results sorted into sweep-data sets and can easily plot them and distinguish the sets.

Yet, by reusing the design during the Smart Sweep the average solver time is 28% shorter compared with the solver time during the sweep. Some simulations did not converge during the standard sweep, while Smart Sweet simulation (reusing previous simulations) converged flawlessly.

I hope the topic of this article is interesting and that you can use this to reach your goals with Simcenter STAR-CCM+ faster. Let us know if you have any questions or comments at support@volupe.com.

[wpdm_package id=’7609′]

The Author

Florian Vesting, PhD

Contact: support@volupe.com

+46 768 51 23 46